Identification of OHS Risks and Hazards

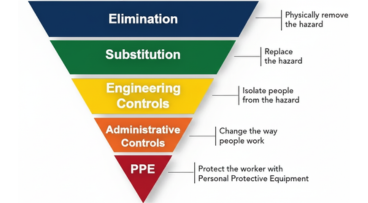

The main element of HIRA is to identify all materials, agents, conditions, or activities that have the potential to cause injury, harm, illness, or damage to the business and its property. To achieve this, we regularly evaluate our processes and job tasks by assessing the associated risks and hazards, ensuring a proactive approach to mitigating potential threats. A key component of our HIRA framework is our hazard reporting mechanism, which encourages all employees to report any incident or hazard to their immediate supervisors and departmental committees, facilitating prompt attention and action. We define a hazard as a source, situation, or act that can potentially harm and result in injury, illness, or a combination of both. Our OHS risks are categorized into six primary areas: physical, mechanical, electrical, chemical, biological, and others, and are prioritized based on their probability, frequency of occurrence, and severity, taking into account the potential adverse impacts, including possible losses and injuries. By regularly evaluating and prioritizing these risks, we are able to implement effective controls and mitigation measures to minimize harm and ensure a safe and healthy work environment.

Angola

Angola

Argentina

Argentina

Bangladesh

Bangladesh

Bolivia

Bolivia

Columbia

Columbia

Costa Rica

Costa Rica

Dominican Republic

Dominican Republic

DRC

DRC

Ecuador

Ecuador

El Salvador

El Salvador

Ethiopia

Ethiopia

GCC

GCC

Guatemala

Guatemala

Guyana

Guyana

Haiti

Haiti

Honduras

Honduras

Kenya

Kenya

Madagascar

Madagascar

Mexico

Mexico

Myanmar

Myanmar

Nepal

Nepal

Nicaragua

Nicaragua

Nigeria

Nigeria

Panama

Panama

Peru

Peru

Philippines

Philippines

South Africa

South Africa

Sri Lanka

Sri Lanka

Tanzania

Tanzania

Trinidad

Trinidad

Turkey

Turkey

Uganda

Uganda

Zambia

Zambia